It’s an thrilling time for manufacturing experts, but your journey with AI begins with trusted custom machining services and products.

Simulating Resource paths: The system simulates various Device paths to establish essentially the most efficient route, reducing material squander and machining time.

This volume of precision is important in industries like aerospace, automotive, and clinical, the place even the slightest deviation can have substantial implications.

Housing and Enclosures: CNC lathes are used to develop metal and plastic housings for Digital devices, making certain they meet exact specifications.

MultiCam's tables are built applying precision laser calibration equipment and weighty steel frames, Consequently making sure precision, durability and stability in the course of cutting processes. A number of MultiCam's styles even occur preloaded with product databases of saved configurations like feed charge and pierce hold off, eliminating the need to reprogram them every time distinct materials are used.

Gather machine method information, which includes machine parameters, efficiency metrics and tooling information. The information you have got serves as being the training ground for the AI algorithms. When you Get your current data, review it to determine designs, anomalies and opportunities for advancement.

When choosing the right measurement CNC lathe, youll wish to evaluate the part measurements O.D. that you will be making. Equally as the axis movement, Reside tooling, and several tooling positions push the complexity of parts that can be manufactured, the bar ability outer diameter measurement determines the scale parts. Bar feeders push the stock through the collets for production operates.

A number of manufacturers have been experiencing the main advantages of AI in CNC machining. These success stories highlight the possible Read for increased efficiency, reduced mistake costs, and optimized production workflows.

Cost Personal savings: Predictive routine maintenance abilities bring on cost financial savings by making certain that machines are often operational and serviced at the correct time.

Its feasible to accomplish all milling and turning operations in a single set up since the machine supports the whole array of milling and turning operations. This is among the most adaptable of every one of the lathes. We now have 5 axis lathe listings offered.

Two types exactly where synthetic intelligence Positive aspects CNC manufacturing probably the most are in productivity and efficiency. It may be argued that every single good thing about AI and deep machine Understanding will immediately or indirectly effect the Main values of shop productivity and efficiency.

Certainly one of the significant enhancements in CAM software program is its seamless integration with CAD (Personal computer-Aided Style and design) tools. Designers can now shift from design to production without leaving their computer software setting, streamlining your complete process.

In One more illustration, an engineering and technology business built-in of AI into its CNC machining. Doing that, they have got revolutionized its high-quality control, accomplishing a 40% reduction in defect premiums. AI-pushed authentic-time high quality monitoring systems consistently evaluate production knowledge and sensor inputs to detect and proper deviations instantly.

How is quantum computing anticipated to affect CNC milling? However nonetheless rising, quantum computing’s ability to course of action huge details concurrently may lead to actual-time optimizations in CNC milling, pushing the boundaries of machine abilities.

Edward Furlong Then & Now!

Edward Furlong Then & Now! Rick Moranis Then & Now!

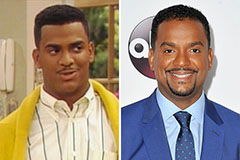

Rick Moranis Then & Now! Alfonso Ribeiro Then & Now!

Alfonso Ribeiro Then & Now! Michael Oliver Then & Now!

Michael Oliver Then & Now! Phoebe Cates Then & Now!

Phoebe Cates Then & Now!